top of page

Academics

Class Projects

These are the various modeling, design, and manufacturing projects created as part of my courses as a mechanical engineering student at the University of California, Santa Barbara.

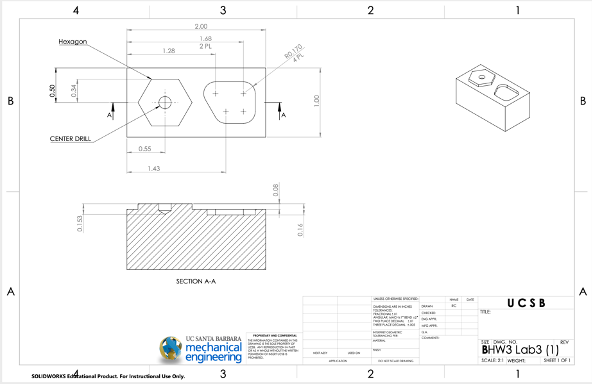

Foam Block on CNC Mill

Purpose:

As part of my CAD/ CAM class, I manufactured this foam block part using a CNC mill given dimensioned machine drawings. This project provided valuable exposure to generating toolpaths through HSM Express, and using the Flashcut CNC software. Further, the proper technique for centering the part using an edge finder was taught.

Implementation:

I first selected the tools and created a toolpath on HSM Express, transporting this g-code onto the Flashcut software. I then secured the foam block into the vise and used the edge finder to center the part on Flashcut CNC. I ran the toolpath above the part as a check, then finally ran the path. Upon completion, I realized the toolpath missed a bit of foam, so I finished the piece off by manually milling the bit off.

CAD Models

Purpose:

These are some of the CAD models I created for my various engineering design class projects. The overarching goal of all of these models was to become familiar with the CAD modeling tools SolidWorks has to offer.

Design:

The first one features Storke Tower, which is central to the UCSB campus, with a sombrero on top representing our mascot the Gaucho. Second model features a ruler to scale. Finally is a “UCSB ENGINEERING” design, with the “ENGINEERING” text cut into the base of the “UCSB” text.

Plexiglass Camera Keychain on Laser Cutter

Purpose:

For my Graphics, CAD and Design class, I had to create and manufacture a design using plexiglass. A Full Spectrum Laser cutter would be utilized to cut and raster the design onto the glass.

Design:

My design features a camera because I like to take pictures and make videos in my free time. The center of the lens has my name on it, and there is a circular hole cut in the top corner to attach to a keychain.

Implementation:

I first modeled the camera outline and design on SolidWorks. I created a drawing from the part, and transferred it over to the Full Spectrum Laser software to program the type of cuts. The outside and keychain circle needed to be fully cut, while the circular lens and my name just needed to be rastered. After centering the plexiglass and running the boarder of the cut, I finally ran the software.

bottom of page